Digital Engineering Adopts 3D Virtual Reality Tools

VR is a key tool in Northrop Grumman's digital toolkit

By Tracy Staedter

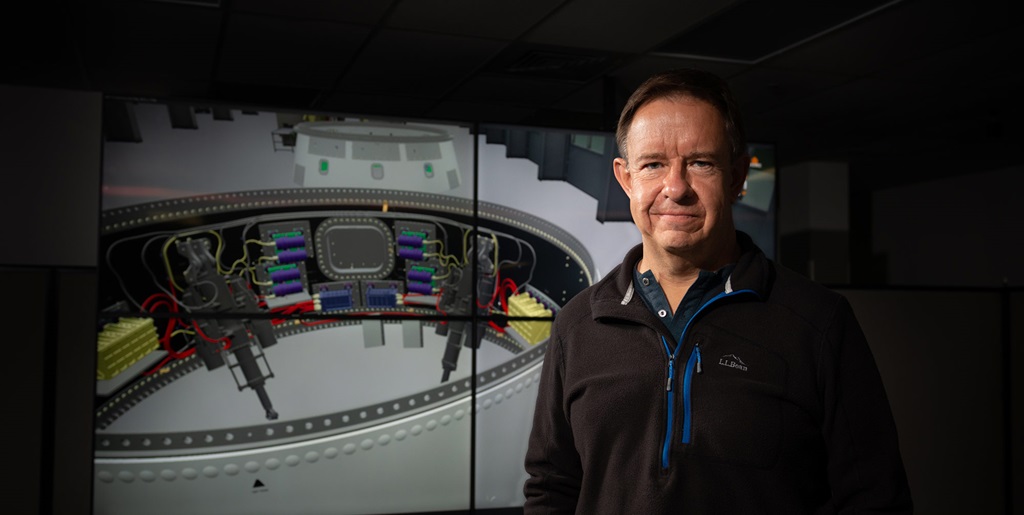

When virtual reality (VR) was first introduced as a tool for digital engineering, Northrop Grumman staff engineer Jim Maul was eager to experiment. His team, led by Nathan Christensen, manager in engineering, put early VR tools to the test as a way to view rocket propulsion systems. It’s easy to imagine that six years ago, the team found that first-generation VR technology was cost prohibitive, only partially immersive and just not up to the task.

Still, Jim saw the potential of this emerging technology and continued to follow it. With the advent of cost effective consumer-grade VR headsets, the team was ready to give the tools another shot.

They quickly learned that VR headsets put this Northrop Grumman digital engineering team in immersive, 360-degree experiences and — paired with high-end, commercial software and high-speed graphics computing capabilities — Maul could quickly convert 3D computer aided design (CAD) models to those that could be viewed in a VR environment. Suddenly, Maul, Christensen and their team could, without much effort, inspect life-size models of rocket engines that had so much detail and clarity, they looked real.

Today, years after their first skeptical experimentation, the team considers VR to be a key tool in their digital toolkit.

Seeing is Believing

Engineers use design reviews to locate errors and address customer concerns. In the early days of space flight, NASA engineers and technicians scrutinized details using two-dimensional drawings and calculation sheets. That evolved into CAD models with scale and full-size physical mock-ups built from wood or metal.

Today engineers can create 3D CAD renderings and, in minutes, convert the file for VR, go to the viewing room, don the headset and examine a full-scale model in extraordinary detail. Because headsets are lightweight and work wirelessly, engineers have the flexibility and freedom to walk entirely around the rocket, examining it inside and out. And with details so precise and realistic, viewers can see the threads on bolts, the twists in wires and the embossed identification labels on various components.

"If a picture is worth a thousand words, VR is worth a thousand pictures," says Christensen.

Northrop Grumman applied its VR techniques while designing a new intermediate-class rocket, and engineers used the technology to respond to questions from the customer. One of those questions had to do with batteries that would have to be replaced in the rocket on the pad just before launch. The batteries weighed 25 pounds each and the design required that they be installed or removed through a small access door. During the design review, an engineer simulated the battery installation in the VR environment using a 25-pound dumbbell.

The VR design review quickly showed engineers and customers that the access panel was placed in an awkward location for a battery exchange. The engineer had to reach around another component, and because the battery was so heavy, installing and removing it became nearly impossible. The simulated environment helped engineers redesign a hanger system that allowed anyone to easily slide the batteries in or out.

The team learned a great deal from the experience they gained designing the new rocket and from applying these capabilities to other products, says Erikson.

"We have demonstrated the great potential AR/VR has to improve our traditional design processes, and we are seeing the advantage of these digital capabilities across many of our programs," Erikson said.

Digital Engineering Improves Outcomes on the Battlefield

Northrop Grumman's VR capabilities shined when vying for a contract with AeroVironment to build the warheads for its Switchblade drone. The unmanned aircraft is small enough to fit into a soldier's backpack and can be rapidly deployed from the ground to strike an adversary up to six miles away. Northrop wanted to demonstrate how its warhead would perform on the battlefield and how its directed fragments would disperse after it exploded — thereby limiting collateral damage. Maul and his team used warhead design simulation results to accurately model the direction and velocity of fragments and then created a VR animation with 3D models of the fragments in a battlefield simulation.

They brought the customers from AeroVironment into the VR lab, a room that's about 30 feet by 30 feet. With a headset on, they took them into a virtual war zone. "You could walk through the scenario, around Humvees and insurgents, and you could see the incoming weapon overhead and see those fragments coming at you," says Maul.

The customers were so impressed with the experience and the performance of the warhead, they awarded Northrop Grumman the contract. "Helping the customer visualize our warhead technology with VR was a key factor in winning what has become a large multimillion dollar program for Northrop Grumman," says Christensen.

Maul says his digital engineering team continues to explore technological capabilities to improve designs. They have set up remote design review capability with another team more than 90 miles away and are currently exploring the use of imaging technology to scan their manufacturing facilities and bring them into the VR environment.

"In VR, you are immersing yourself into the visual movie of engineering. You can see your designs, interact with them, see the manufacturing process, collaborate with others in these processes and even ‘simulate’ those designs being used in the real world," says Maul. "Only your imagination is holding you back.”

More innovation stories

Read all stories about advanced technology and innovation >>