Brawn, Brains and Beauty

Industry 4.0 in Manufacturing

By Kelly McSweeney

Look around, there’s evidence everywhere; we are on the journey to the fourth industrial revolution. Each previous industrial revolution has represented a leap of faith and a progression from the one before it, integrating new changes with better use of existing tools and the application of new ones. The current transformation – known as Industry 4.0 – is no different. Industry 4.0 is about leveraging four key digital technologies to optimize resources, enable faster decision making based on real-time data, and to produce higher quality products at a reduced cost.

These following existing and new technologies are the key drivers to Industry 4.0:

- Connectivity: to data from manufacturing & facility assets through connected sensors (Industrial Internet of Things, Smart Factory)

- Analytics & Intelligence: data analytics & visualization of shop floor operations & assets digitally displayed. Advanced predictive analytics though Artificial Intelligence (AI) & Machine Learning (ML)

- Extended Reality: increased human machine interaction to engineering & manufacturing systems through Augmented Reality (AR) / Virtual Reality (VR)

- Advanced Manufacturing: robotics, autonomous systems, and additive manufacturing (3-D Printing)

What's Powering Industry 4.0? - from Brawn to Brains

Today there is more access to data and the ability to analyze and visualize that data in a meaningful way. Wireless communication, Industrial Internet of Things (IIoT), artificial intelligence and computing power have all greatly improved in the last decade. By connecting machines (Brawn) to key business systems and applying analytics & intelligence to the connected data (Brains) enables real-time decisions.

As a result, modern industrial facilities are now being equipped with robots that can do heavy lifting and machines with sensors on every moving part. These connected sensors and machines with applied analytics & intelligence is what industry calls a “Smart Factory”. The value comes from connecting machines together in a "digital thread" of communication and analyzing the data on a deeper level to make decisions.

“Industry 4.0 is helping us ‘connect’ across the program lifecycle and transform data into decision-ready information at the right place and at the right time,” says Chris Orlowski, Director, Digital Engineering at Northrop Grumman. “By enabling data-as-a-service and connecting our environments across engineering, manufacturing, and sustainment, we are able to accelerate our product development processes to meet the urgent needs of our customers”

Industry 4.0 gives the ability to interact with data and designs by extending a person’s reality to interact in a completely immersive virtual environment. Transitioning from a two-dimensional (2-D) world, engineers can now examine designs in a virtual environment much earlier in the design life cycle.

Finally, any discussion with data and connectivity involves a conversation about building a cyber-resilient architecture to protect the data and how we use that data to make discussions. Connected manufacturing involves adding countless sensors and IP addresses to the factory floor.

"Cyber resiliency is going to be a foundational value for the digital transformation," says Sarat Saluru, Senior Principal Systems Engineer at Northrop Grumman.

How do you capitalize on Industry 4.0? – From Brains to Beauty

The beauty of this connectivity is using predictive analytics in a visually digestible format to become more efficient to minimize defective parts by optimizing downtime. For example, with Industry 4.0, personnel can track a machine's health and use data analytics to predict when a machine will require maintenance. Then, instead of shutting the entire operation down when a tool wears down, you can proactively schedule maintenance so that your overall volume and production will be consistent.

"If we have sensors on all the key parts of the machines, we know when they are going to wear out, down to the minute," says Zach DeSmit, Senior Principal Systems Engineer at Northrop Grumman. "That way, we're not wasting resources by swapping out good parts preemptively, and we're eliminating downtime."

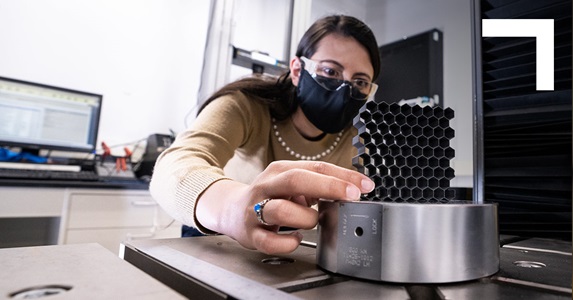

“One of the true beauties of Industry 4.0 is the ability to take a design concept and within hours we can validate that design’s producibility and accessibility in a virtual environment or by 3-D printing the part or assembly.” says Ignacio Serrano, Manager of Transformational Manufacturing at Northrop Grumman.

Within a digitally connected ecosystem, 3-D models can be quickly converted into a format that allows the designer and end user to review the design in the virtual environment. By leveraging the virtual experience and 3-D printing, it helps us to improve and iterate the design before we start manufacturing, reducing costs downstream while improving first time quality.

As products have become more complex, it has created a core of very specialized skills required of technicians to perform critical operations. To aid our specialized workforce we have leveraged advanced manufacturing techniques to enable them to better execute. This can be anywhere from composite layups to drilling and precision assembly operations. Furthermore, 3-D printing enables our technicians to get hands on experience with a product to learn and transfer skills prior to the start of manufacturing.

In the end, beauty is in the eye of the beholder and “Industry 4.0 is part of our overall digital transformation effort and is essential for us to remain competitive in this market,” says Keith Matthews, Director of Materials, Manufacturing, Integration Test & Launch.

More innovation stories

Read all stories about advanced technology and innovation >>