ESD PEKK: The Additive Acronym of Advanced Aerospace Manufacturing

Higher. Further. Faster.

By Doug Bonderud

Higher. Further. Faster. This is the cognitive drumbeat of aerospace innovation, embodied as the quest to find new and better ways of breaking Earth's bonds, taking to the skies and even exploring the stars.

Process tends to be the priority for paradigm shifts — such as the move to robotic assembly architectures and data-driven stress testing. But the evolution of additive manufacturing, also known as 3D printing, has opened a new door for discovery: advanced materials. One such additive advantage comes from electrostatic dissipative PolyEtherKetoneKetone (ESD PEKK), which according to Northrop Grumman fellow Eric Barnes, "makes aircraft cheaper, lighter-weight and faster to build."

But how does this high-performance thermoplastic work? What benefits does it offer? And what does it mean for the future of aerospace manufacturing frameworks? Let's dive in.

Solving the Static Quo

Static is a serious problem for aircraft. Just as static electricity can build up when you rub a balloon on your hair or scuff your socks along a rug, so too can static charge quickly accumulate in critical craft controls. Without an easy discharge path, it can cause significant damage or even systems failure.

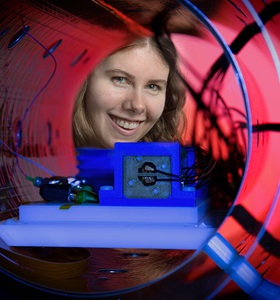

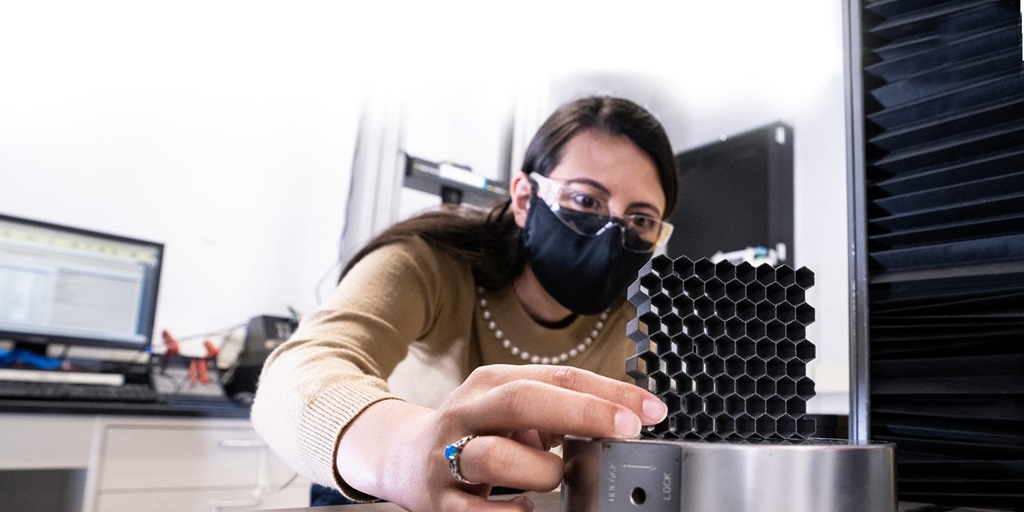

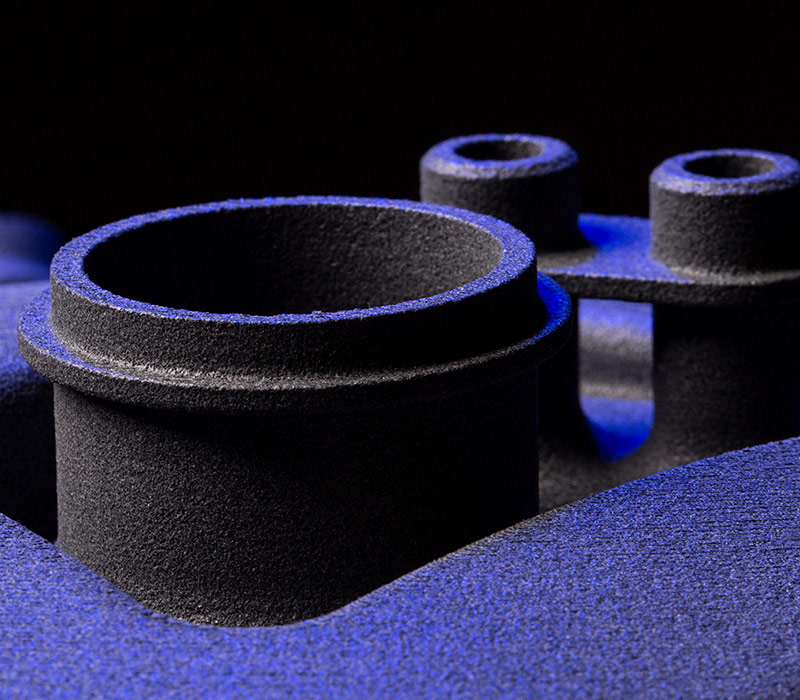

ESD PEKK helps solve this problem through the use of discontinuous carbon fibers. In practice, this means adding carbon fiber to additive manufacturing material powder, which is then placed in a vat and melted by lasers at precise locations, layer by layer. This creates a natural outlet for static discharge in environmental and other aerospace systems.

"You want it to go somewhere to prevent it," says Barnes, "so we incorporate carbon fiber." What's more, the distribution of carbon throughout the material means that no matter the system and no matter its location, it's protected by a discontinuous defense.

Delivering Dynamic Performance

While shaking off shocks is a significant benefit of this advanced aerospace manufacturing material, that's not its only advantage.

"One of the benefits as compared to other high-performance thermoplastic is its relatively easy to process," notes Barnes. "It brings a lot of really good performance properties to our applications." In addition, ESD PEKK meets key requirements set out by the Federal Aviation Administration (FAA) for building crewed aircraft, including:

- Improved thermal stability: Even when facing extreme temperature increases or sudden changes, this thermoplastic remains stable, making it ideal for high-stress atmosphere applications.

- Enhanced chemical resistance: Many polymer-based materials are compromised by chemical solvents and liquids; ESD PEKK offers substantively improved resistance to chemical corrosion.

- Reduced radiation damage: For most polymers, space-borne gamma radiation causes structural breakdown, but this new material is minimally affected by radioactive exposure.

- Absent outgassing: As Barnes notes, outgassing is a significant problem in space. "When you put material in a vacuum in space, especially polymers, some of the molecules can come off and float around. Eventually, they attach to something and create a film," he says. Over time, this film poses both functional issues for the craft and survivability problems for the crew, especially in confined spaces. However, this advanced thermoplastic produces no outgassing in a vacuum environment, making it safe for spacecraft manufacturing.

Barnes makes the benefits of ESD PEKK clear: "It survived unique space environments with gamma radiation, outgassing and thermal cycling requirements that most polymers do not meet."

Manufacturing the Future of Flight

But inherent material benefits are only half the battle — ESD PEKK also delivers when it comes to the speed, safety and scalability of aerospace manufacturing.

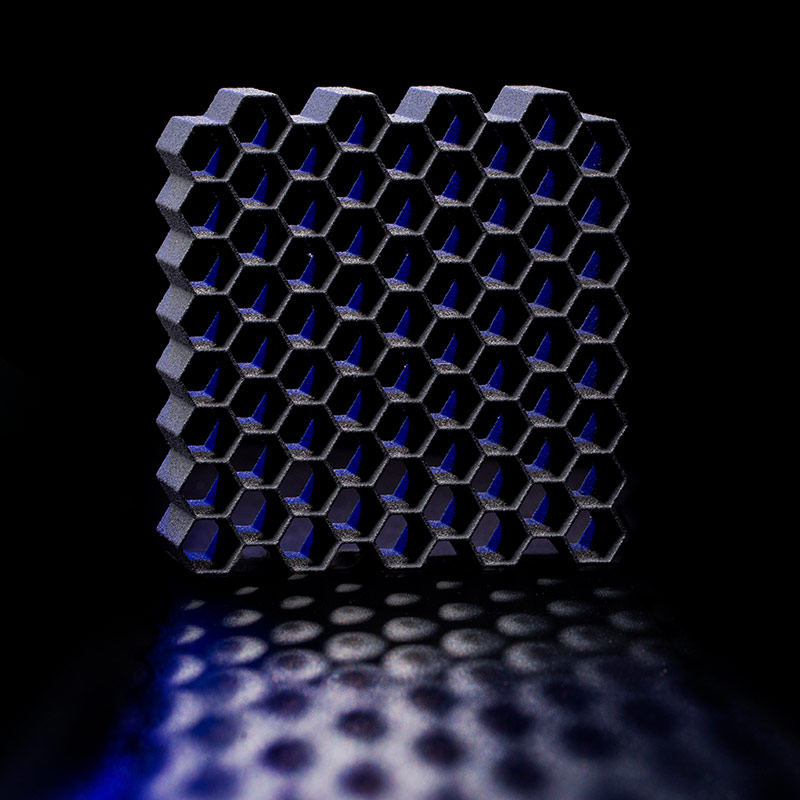

By printing approved aircraft parts as single units rather than multiple pieces, manufacturers can reduce total weight and improve flying time. This advanced thermoplastic also offers increased flexibility in design and deployment because it can be used to create many things, including ductwork, access covers, brackets and craft-specific tools.

"It gives us creative freedom without worrying about the cost or time penalties," says Barnes.

Also critical? Volume. In small-space applications, such as fighter craft or space shuttle cockpits, ESD PEKK makes it possible to print parts that fit as part of a larger plan rather than individual items.

"We have the potential to design all these subsystems, such as ducting and heat exchangers, to fit volumetrically, like a jigsaw puzzle," says Barnes. "Because you can tailor all these shapes to fit like a jigsaw puzzle, you can fit more stuff in an airplane belly or fuselage."

When it comes to aerospace manufacturing, advanced thermoplastics such as ESD PEKK pave the way for faster builds that meet higher performance thresholds and help to further the future of human innovation.

More innovation stories

Read all stories about advanced technology and innovation >>